- Joined

- Oct 13, 2019

Essential stl files of all kinds, primarily firearms and hunting equipment. What i hope to do with this thread is to build a separate 3d printed firearms repository besides odysee and other websites.

First file that ive featured is the JAG17 aka just a glock 17.

Its a well made/modelled glock 17 frame by laffs dynamics on odysee. Ive chosen this because glocks are easy to build and are widely available parts wise. These can be built roughly in a day for sub $600 (complete slide + lower parts kit + appropriate metal rails + printed frame + magazine). Ive gotten mine down to five hours per print on the bambu labs x1c.

I'd like to separate my posts however ill refrain from double posting.

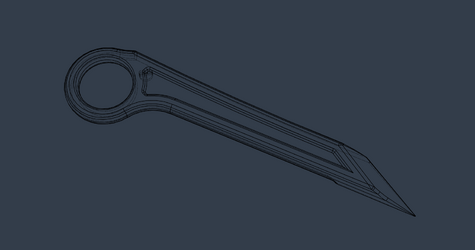

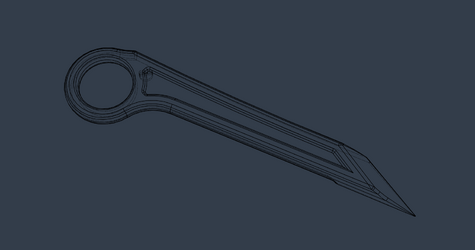

The second file to be featured is the Shrike puncture tool once again created by laffs dynamics.

This tool is designed for puncturing soft flesh and can be used as a letter opener

-------

-------

Introduction to printing firearms LEGALLY.

I truly believe in educating when i see misinformation being spread esp about the things that i am extremely knowledgeable about. This info that I am providing to you should be built upon and in no way should you not do your own research. I got to where I am in this hobby by doing my own research and am of average to above average intelligence. You too can learn what ive learned by just searching for relative information on the internet.

above all I strive to help people understand their legal rights as well as how to observe the law from an average uninformed perspective aka a normal persons view. Everyone should understand what they can and cant do to some degree .

.

With that being said I will divulge into my vast understanding about 3d printed firearms.

3D PRINTED FIREARMS/CONCEPTION TO USEABLE FIREARM -

3d printed firearms are legal to own and build in the state of PA. There are many steps that go from idea to actual usable firearm. My goal is to provide the general public (you) with helpful info on how 3d printed firearms are conceptualized, built, used, and are found as well as how to combat myths surrounding them.

To begin we need to conceptualize and think of how to bring this idea into existence. There are plenty of things you must know how to do before you can even print a frame(legally the firearm).

1.PRINTER SETUP/ USAGE AND FUNCTIONS

Printer type does not matter(typically recommended are Ender products), all you need is a big enough build plate and the knowledge to problem solve and you can eventually build a firearm. This can all be sped up by spending more money on a machine that has auto bed leveling and significant speed increases, faster = less build time = faster turn around on production.

There are very particular settings that you MUST have in order for the frame to be usable and not fail immediately. I will not go into exact settings because i am not here to teach you how to EXACTLY build them but how one would go about identifying REAL USEABLE QUALITY in a print. Some terms to research would be wall thickness, infill density, layer height, build plate temp, nozzle temp, fan speed, wall count, brim, deburring, support infill density, and print orientation.

These terms are crucial to a successful, useable print. typically you will want to deconstruct the assembled firearm down to the printed frame. after all parts(upper assembly, lower parts kit, METAL rails and pins) are removed, you can take a look at the print orientation and determine if it was printed RAILS UP or RAILS DOWN... or diagonal aka wrong(in terms of printing standard handgun and ar15 receivers dont do diagonal). Another way to check the p.o. is to take a look at the trigger guard or pic rails under the slide/guide rod). If you notice an uneven stringy surface that looks VERY messy, you may be able to determine that the firearm was printed RAILS UP. now that youve determined the p.o. you can take a look at the walls and get an understanding of how they look and maybe even how many there are. This also allows you to determine other info that may help identify other build processes.

2.BED LEVELING -

First you need to be able to level the print bed regularly, this effects LITTERALY every thing related to the accuracy of your print. once youve achieved bed leveling accuracy the next step is problem solving. Bed leveling is the 3d printing litmus test, you can A. master it so you understand the process and how it affects your prints OR B. skip it entirely and wing it and run into FIXABLE problems later on. I benefited extremely from building an ender product and then learning bed leveling, it taught me a skill that will be used forever. bed leveling manually can be achieved with simple math and a piece of paper, there are even videos explaining this extensively online.

3.PROBLEM SOLVING/ TESTING

Before you can even begin to print a frame you must test your skills and your machine. Common methods of testing that are regularly used are calibration cubes, however these are only the first step in identifying problems. basically you want to get your calibration cube as perfect as possible THEN you can transfer that knowledge to all of your other prints. Now a bit about supports, supports are the hardest thing to get down esp for printing a useable frame. in my experience ive run into problems with supports the most, what are supports? supports are critical pieces of plastic that provide a surface for you to eventually print on. Supports NEED to be dialed in almost perfectly!!!! your supports will get BAKED into the print PERMANANTLY if you do not have the correct settings and will render your frame unusable. The only way that ive found to fix your support woes is trial and error. ive printed MANY iterations of the same frame over and over again just because of support settings being SLIGHTLY off. Id say it takes about 10 trys from no experience with 3d printing to get to a useable frame. Ten trys is about lets say five hours printing time each try, minus after work / deburring. In essence, you should be able to remove your supports with minimal effort so that they practically pop right off without leaving any remaining plastic. IMAGE HERE. your supports should not require almost ANY after work in regards to removing material besides tight spots like pin holes or internal supported areas. in my experience i only print RAILS UP, why? well thats because the internal area where all the parts go (upper, lower parts kit, metal rails,pins) are UN OBSTRUCTED by supports. this is very important because you can basically guarantee accurate fitment with almost no rework, as opposed to RAILS DOWN where as ALL of the internals will be touching supports.

4. FILE LOCATION / REALIZATION THAT YOU HAVE CORRECT FILES -

Once you have your settings dialed in and youve tested your printers accuracy, you can now learn how to find the proper files(.stl,.step,zipped files/winRAR) for printing frames. This is again one of the 3d printing litmus tests, where do you find a file that you can trust? How do you know its structurally sound enough to not esplode/crack/fail? Well, the solution is trial and error oh and YOU SHOULD NEVER PAY FOR ANYTHING!!!! All of the files i use are open source and free , and are LEGALLY hosted. DO NOT TRUST OR SUPPORT DARKWEB/CLEARWEB FILE SELLERS! They will fuck you over, they will steal your info, and most importantly they wont be 100% guaranteed useable. you are better off reading REDDIT and watching YOUTUBE than you are paying for any file. Ive learned every thing about files, where they are located and how to determine they work by reading reddits FOSSCAD subreddit and watching freely available youtube videos. These files are semi hidden until you know where to look and how to navigate certain websites. One of these IMPORTANT websites is ODYSEE.COM. ODYSEE.COM is un needlessly hard to navigate, you must know how to even use the search function and refine it in order to even find files.

, and are LEGALLY hosted. DO NOT TRUST OR SUPPORT DARKWEB/CLEARWEB FILE SELLERS! They will fuck you over, they will steal your info, and most importantly they wont be 100% guaranteed useable. you are better off reading REDDIT and watching YOUTUBE than you are paying for any file. Ive learned every thing about files, where they are located and how to determine they work by reading reddits FOSSCAD subreddit and watching freely available youtube videos. These files are semi hidden until you know where to look and how to navigate certain websites. One of these IMPORTANT websites is ODYSEE.COM. ODYSEE.COM is un needlessly hard to navigate, you must know how to even use the search function and refine it in order to even find files.

GOES INTO DETAIL ON HOW TO NAVIGATE ODYSEE.COM HERE -

5.FILES FOUND, NOW WHAT? -

great you have found useable CORRECT files from a trusted open source with plenty of documentation. time to verify they are the ones you want/need, go to the zipped file and try and open it. see if it looks like the examples on REDDIT, take a look at the current hyped build project(could be literally anything from standard 9mm glock frame to a 26mm/whatever mm signal launcher). pick the EASIEST most documented build to start with that you can find(I recommend a simple glock frame because they are constantly released and are simple to build and have been widely tested/reworked). Now that youve selected your build, open the file and see all the included items, youll want to navigate to the READ ME file/ BUILD REQUIREMENTS. It is always necessary to read ALL documentation before you even begin to print ANY parts as there could be weird settings that affect the littlest of details(could be orientation, wall count, whether or not supports are needed, fan temp, bed temp, nozzle size ect.). There should be plenty of visual aids that you can use either included in the zip OR are online that you must find for reference purposes. Now that you are familiar with the requirements to print your build/frame/whatever you must know how to use a slicer(software that is typically included with your printer OR is available for download off a trusted LEGAL website). The slicer is important because it allows you to see how your frame/part will be printed and in alot of ways will allow you to solve problems before you test print. it will show you the tool path, as well as all features relating to orientation and print time.

6. MYTHS / NONSENSE YOU HEAR ABOUT 3D PRINTED FIREARMS -

So commonly you will run into naysayers, liars, GOVERNMENT SPONSERED OPPOSITION(can be foreign aka non usa OR usa based . These people are evil minded retards that need to be delt with logically through proof of concept and proof of work, simply teaching them that they are wrong is enough to inform someone that they are logically proven to be wrong in their thinking.

. These people are evil minded retards that need to be delt with logically through proof of concept and proof of work, simply teaching them that they are wrong is enough to inform someone that they are logically proven to be wrong in their thinking.

intro -

common myths will be used by naysayers to obstruct progress at any and every opportunity. these people are so mentally retarded that they cannot grasp the concept that they are wrong in their thinking. The only way to disprove these people is with logic and math. you will need to force people with this myth mindset to understand that they are wrong. one thing that i always bring up is that the cartridge determines the amount of force/gas/pressure, these are all contained by METAL PARTS. anything possibly load bearing is metal except for the frame. so in essence you only need to worry about A. where the firearm is pointed, B. the frame is built to settings that are referenced from the instructions/READ ME, C. the cartridge is not defective and D. you wear ppe/eye protection/hearing protection/thick durable gloves(if you decide to hand fire it).

myth 1 guns always fail -

most guns do not fail if built correctly (there are ways to check for this once assembled, you do not need to test fire them). there are two specific failure points that i recognize as being problematic, these are located at the PINS and typically at the SLIDE ASSEMBLY. two things that can happen if you incorrectly print the frame, A. the frame cracks at the pins after one shot, rendering it unusable and B. the slide fires backwards(rear end of the slide slides off the back of the frame towards you) and shoots off of the frame.

A is more likely to happen than B. but this is all determined by build quality and assembly, there are tolerances to making these frames usable but they can be jerry rigged to a certain degree. Ive seen more videos of successes than failures.

myth 2 legality -

Once again there will be plenty of people that say what you are doing is illegal regardless of what you tell them. These people are a detriment to society and should be told that they are wrong using logic and the law. Simply educate yourself on what your local state laws are regarding making 3d printed firearms. some states it is outright illegal to print a firearm and in others there's practically no regulation whatsoever.

****

EDUCATE YOURSELF and OTHERS on local laws, consult a lawyer specifically designated in the 3d printing of firearms and get REAL legal advice if you feel uncomfortable printing receivers/frames. ALWAYS do your own research and if possible consult a professional attorney. I cannot stress this enough that you should be doing this legally.

****

myth 3 they are easy to make -

once again you will run into mentally defective people that assume making a 3d printed firearm is so simple that a common low iq criminal can make one in a matter of seconds. This is simply retarded, from conception to firearm it will take you over ten hours and at least five hours to print the frame alone. There is so much that you need to know how to do, that it is baffling to me when i see news anchors/journalists/members of Congress/the media? sperg out and scream that "you can build a gun at home, FAST!!!!".

its simply just bad propaganda at this point that its laughable. Ill be politically correct here when i say that the majority of people that are smart enough to endure this ENTIRE process and build a useable firearm are not the ones DIRECTLY shooting brothas on the corner. These crimes are being committed with these 3d printed firearms directly by LOW IQ "scholars" and as the media likes to call them "good boys that didnt do nothing"-_-).

myth 4 the gun will "esplode" -

reminder that it will not "esplode" if you follow the instructions and know how to problem solve(and even then it wont send plastic shrapnel into your face and throat .

.

6. TESTING THE FIREARM -

There are plenty of safe ways to test your completed 3d printed firearm. One of which is just simply making sure a dummy round cycles. By cycling a "round" you can understand that the gun functions properly, this can be done without lubricant being applied to the rails and points of contact with the slide. Another way is to live fire the gun which is a lot harder to do. first you must secure a legal location to do this at, surprisingly enough you can bring 3d printed guns into most firing ranges. you can also build a bullet trap which eliminates the need for a range(this method is very dangerous in my understanding so i dont mess with testing beyond the cycle test). you can also find a suitable legal location that is not a range where you can safely fire your gun, in this case lets say you're out on your property far enough away where you can shoot a gun. with this method you can fasten your gun to some sort of metal stand(blocks of wood etc) and safely from a distance pull the trigger and test it. you can also test by holding the gun while you fire it(wear ppe and you most likely will be fine). hold away from your head the fist couple of shots until you feel comfortable firing normally.

WEBSITES/SEARCH TERMS TO USE -

do some research but these are the usual places people get parts, ideas, and files.

reddit/fosscad, avesrails, other parts kits websites like parts dispensed, odysee, yeggi(search engine for stls), thingieverse(occasionally there are files), tinkercad(allows you to rework things), autoCAD based software, slicers, DO NOT TRUST DEFCAD EVER, ivanthetroll, navigoesboom, plastikov, mac11 wind chimes kit.

AFTERWORDS / PERSONAL THOUGHTS -

What i have given you is a starting point that no one else online or irl will give you, please be careful and please read your local laws. Building firearms is legal in Pennsylvania and I hope with this minimal info people will understand that aside from da brothas on tha street there are actual hobbyists that just love to build guns legally.

I never even intended to get into this hobby, it found me by chance. I was so bored with my life and job that i decided to take this up and its only been like two years and i took a six month break. Average people can do this, but not below average people like the ones using these guns as weapons. It takes a special kind of retard to spend all this time and effort just to kill someone especially when its easier to buy a gun ILLEGALLY ON THE STREET(you could buy one legally way easier than printing one).

my objective with my writing is to force understanding upon people that do not understand, hopefully this helped explain some things and provided you with minimal information.

First file that ive featured is the JAG17 aka just a glock 17.

Its a well made/modelled glock 17 frame by laffs dynamics on odysee. Ive chosen this because glocks are easy to build and are widely available parts wise. These can be built roughly in a day for sub $600 (complete slide + lower parts kit + appropriate metal rails + printed frame + magazine). Ive gotten mine down to five hours per print on the bambu labs x1c.

I'd like to separate my posts however ill refrain from double posting.

The second file to be featured is the Shrike puncture tool once again created by laffs dynamics.

This tool is designed for puncturing soft flesh and can be used as a letter opener

-------

-------

Introduction to printing firearms LEGALLY.

I truly believe in educating when i see misinformation being spread esp about the things that i am extremely knowledgeable about. This info that I am providing to you should be built upon and in no way should you not do your own research. I got to where I am in this hobby by doing my own research and am of average to above average intelligence. You too can learn what ive learned by just searching for relative information on the internet.

above all I strive to help people understand their legal rights as well as how to observe the law from an average uninformed perspective aka a normal persons view. Everyone should understand what they can and cant do to some degree

With that being said I will divulge into my vast understanding about 3d printed firearms.

3D PRINTED FIREARMS/CONCEPTION TO USEABLE FIREARM -

3d printed firearms are legal to own and build in the state of PA. There are many steps that go from idea to actual usable firearm. My goal is to provide the general public (you) with helpful info on how 3d printed firearms are conceptualized, built, used, and are found as well as how to combat myths surrounding them.

To begin we need to conceptualize and think of how to bring this idea into existence. There are plenty of things you must know how to do before you can even print a frame(legally the firearm).

1.PRINTER SETUP/ USAGE AND FUNCTIONS

Printer type does not matter(typically recommended are Ender products), all you need is a big enough build plate and the knowledge to problem solve and you can eventually build a firearm. This can all be sped up by spending more money on a machine that has auto bed leveling and significant speed increases, faster = less build time = faster turn around on production.

There are very particular settings that you MUST have in order for the frame to be usable and not fail immediately. I will not go into exact settings because i am not here to teach you how to EXACTLY build them but how one would go about identifying REAL USEABLE QUALITY in a print. Some terms to research would be wall thickness, infill density, layer height, build plate temp, nozzle temp, fan speed, wall count, brim, deburring, support infill density, and print orientation.

These terms are crucial to a successful, useable print. typically you will want to deconstruct the assembled firearm down to the printed frame. after all parts(upper assembly, lower parts kit, METAL rails and pins) are removed, you can take a look at the print orientation and determine if it was printed RAILS UP or RAILS DOWN... or diagonal aka wrong(in terms of printing standard handgun and ar15 receivers dont do diagonal). Another way to check the p.o. is to take a look at the trigger guard or pic rails under the slide/guide rod). If you notice an uneven stringy surface that looks VERY messy, you may be able to determine that the firearm was printed RAILS UP. now that youve determined the p.o. you can take a look at the walls and get an understanding of how they look and maybe even how many there are. This also allows you to determine other info that may help identify other build processes.

2.BED LEVELING -

First you need to be able to level the print bed regularly, this effects LITTERALY every thing related to the accuracy of your print. once youve achieved bed leveling accuracy the next step is problem solving. Bed leveling is the 3d printing litmus test, you can A. master it so you understand the process and how it affects your prints OR B. skip it entirely and wing it and run into FIXABLE problems later on. I benefited extremely from building an ender product and then learning bed leveling, it taught me a skill that will be used forever. bed leveling manually can be achieved with simple math and a piece of paper, there are even videos explaining this extensively online.

3.PROBLEM SOLVING/ TESTING

Before you can even begin to print a frame you must test your skills and your machine. Common methods of testing that are regularly used are calibration cubes, however these are only the first step in identifying problems. basically you want to get your calibration cube as perfect as possible THEN you can transfer that knowledge to all of your other prints. Now a bit about supports, supports are the hardest thing to get down esp for printing a useable frame. in my experience ive run into problems with supports the most, what are supports? supports are critical pieces of plastic that provide a surface for you to eventually print on. Supports NEED to be dialed in almost perfectly!!!! your supports will get BAKED into the print PERMANANTLY if you do not have the correct settings and will render your frame unusable. The only way that ive found to fix your support woes is trial and error. ive printed MANY iterations of the same frame over and over again just because of support settings being SLIGHTLY off. Id say it takes about 10 trys from no experience with 3d printing to get to a useable frame. Ten trys is about lets say five hours printing time each try, minus after work / deburring. In essence, you should be able to remove your supports with minimal effort so that they practically pop right off without leaving any remaining plastic. IMAGE HERE. your supports should not require almost ANY after work in regards to removing material besides tight spots like pin holes or internal supported areas. in my experience i only print RAILS UP, why? well thats because the internal area where all the parts go (upper, lower parts kit, metal rails,pins) are UN OBSTRUCTED by supports. this is very important because you can basically guarantee accurate fitment with almost no rework, as opposed to RAILS DOWN where as ALL of the internals will be touching supports.

4. FILE LOCATION / REALIZATION THAT YOU HAVE CORRECT FILES -

Once you have your settings dialed in and youve tested your printers accuracy, you can now learn how to find the proper files(.stl,.step,zipped files/winRAR) for printing frames. This is again one of the 3d printing litmus tests, where do you find a file that you can trust? How do you know its structurally sound enough to not esplode/crack/fail? Well, the solution is trial and error oh and YOU SHOULD NEVER PAY FOR ANYTHING!!!! All of the files i use are open source and free

GOES INTO DETAIL ON HOW TO NAVIGATE ODYSEE.COM HERE -

5.FILES FOUND, NOW WHAT? -

great you have found useable CORRECT files from a trusted open source with plenty of documentation. time to verify they are the ones you want/need, go to the zipped file and try and open it. see if it looks like the examples on REDDIT, take a look at the current hyped build project(could be literally anything from standard 9mm glock frame to a 26mm/whatever mm signal launcher). pick the EASIEST most documented build to start with that you can find(I recommend a simple glock frame because they are constantly released and are simple to build and have been widely tested/reworked). Now that youve selected your build, open the file and see all the included items, youll want to navigate to the READ ME file/ BUILD REQUIREMENTS. It is always necessary to read ALL documentation before you even begin to print ANY parts as there could be weird settings that affect the littlest of details(could be orientation, wall count, whether or not supports are needed, fan temp, bed temp, nozzle size ect.). There should be plenty of visual aids that you can use either included in the zip OR are online that you must find for reference purposes. Now that you are familiar with the requirements to print your build/frame/whatever you must know how to use a slicer(software that is typically included with your printer OR is available for download off a trusted LEGAL website). The slicer is important because it allows you to see how your frame/part will be printed and in alot of ways will allow you to solve problems before you test print. it will show you the tool path, as well as all features relating to orientation and print time.

6. MYTHS / NONSENSE YOU HEAR ABOUT 3D PRINTED FIREARMS -

So commonly you will run into naysayers, liars, GOVERNMENT SPONSERED OPPOSITION(can be foreign aka non usa OR usa based

intro -

common myths will be used by naysayers to obstruct progress at any and every opportunity. these people are so mentally retarded that they cannot grasp the concept that they are wrong in their thinking. The only way to disprove these people is with logic and math. you will need to force people with this myth mindset to understand that they are wrong. one thing that i always bring up is that the cartridge determines the amount of force/gas/pressure, these are all contained by METAL PARTS. anything possibly load bearing is metal except for the frame. so in essence you only need to worry about A. where the firearm is pointed, B. the frame is built to settings that are referenced from the instructions/READ ME, C. the cartridge is not defective and D. you wear ppe/eye protection/hearing protection/thick durable gloves(if you decide to hand fire it).

myth 1 guns always fail -

most guns do not fail if built correctly (there are ways to check for this once assembled, you do not need to test fire them). there are two specific failure points that i recognize as being problematic, these are located at the PINS and typically at the SLIDE ASSEMBLY. two things that can happen if you incorrectly print the frame, A. the frame cracks at the pins after one shot, rendering it unusable and B. the slide fires backwards(rear end of the slide slides off the back of the frame towards you) and shoots off of the frame.

A is more likely to happen than B. but this is all determined by build quality and assembly, there are tolerances to making these frames usable but they can be jerry rigged to a certain degree. Ive seen more videos of successes than failures.

myth 2 legality -

Once again there will be plenty of people that say what you are doing is illegal regardless of what you tell them. These people are a detriment to society and should be told that they are wrong using logic and the law. Simply educate yourself on what your local state laws are regarding making 3d printed firearms. some states it is outright illegal to print a firearm and in others there's practically no regulation whatsoever.

****

EDUCATE YOURSELF and OTHERS on local laws, consult a lawyer specifically designated in the 3d printing of firearms and get REAL legal advice if you feel uncomfortable printing receivers/frames. ALWAYS do your own research and if possible consult a professional attorney. I cannot stress this enough that you should be doing this legally.

****

myth 3 they are easy to make -

once again you will run into mentally defective people that assume making a 3d printed firearm is so simple that a common low iq criminal can make one in a matter of seconds. This is simply retarded, from conception to firearm it will take you over ten hours and at least five hours to print the frame alone. There is so much that you need to know how to do, that it is baffling to me when i see news anchors/journalists/members of Congress/the media? sperg out and scream that "you can build a gun at home, FAST!!!!".

its simply just bad propaganda at this point that its laughable. Ill be politically correct here when i say that the majority of people that are smart enough to endure this ENTIRE process and build a useable firearm are not the ones DIRECTLY shooting brothas on the corner. These crimes are being committed with these 3d printed firearms directly by LOW IQ "scholars" and as the media likes to call them "good boys that didnt do nothing"-_-).

myth 4 the gun will "esplode" -

reminder that it will not "esplode" if you follow the instructions and know how to problem solve(and even then it wont send plastic shrapnel into your face and throat

6. TESTING THE FIREARM -

There are plenty of safe ways to test your completed 3d printed firearm. One of which is just simply making sure a dummy round cycles. By cycling a "round" you can understand that the gun functions properly, this can be done without lubricant being applied to the rails and points of contact with the slide. Another way is to live fire the gun which is a lot harder to do. first you must secure a legal location to do this at, surprisingly enough you can bring 3d printed guns into most firing ranges. you can also build a bullet trap which eliminates the need for a range(this method is very dangerous in my understanding so i dont mess with testing beyond the cycle test). you can also find a suitable legal location that is not a range where you can safely fire your gun, in this case lets say you're out on your property far enough away where you can shoot a gun. with this method you can fasten your gun to some sort of metal stand(blocks of wood etc) and safely from a distance pull the trigger and test it. you can also test by holding the gun while you fire it(wear ppe and you most likely will be fine). hold away from your head the fist couple of shots until you feel comfortable firing normally.

WEBSITES/SEARCH TERMS TO USE -

do some research but these are the usual places people get parts, ideas, and files.

reddit/fosscad, avesrails, other parts kits websites like parts dispensed, odysee, yeggi(search engine for stls), thingieverse(occasionally there are files), tinkercad(allows you to rework things), autoCAD based software, slicers, DO NOT TRUST DEFCAD EVER, ivanthetroll, navigoesboom, plastikov, mac11 wind chimes kit.

AFTERWORDS / PERSONAL THOUGHTS -

What i have given you is a starting point that no one else online or irl will give you, please be careful and please read your local laws. Building firearms is legal in Pennsylvania and I hope with this minimal info people will understand that aside from da brothas on tha street there are actual hobbyists that just love to build guns legally.

I never even intended to get into this hobby, it found me by chance. I was so bored with my life and job that i decided to take this up and its only been like two years and i took a six month break. Average people can do this, but not below average people like the ones using these guns as weapons. It takes a special kind of retard to spend all this time and effort just to kill someone especially when its easier to buy a gun ILLEGALLY ON THE STREET(you could buy one legally way easier than printing one).

my objective with my writing is to force understanding upon people that do not understand, hopefully this helped explain some things and provided you with minimal information.

Attachments

Last edited: