- Joined

- Jan 1, 2023

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mega Rad Gun Thread

- Thread starter The Hunter

- Start date

Historical Strelkov

kiwifarms.net

- Joined

- Sep 4, 2023

Rodalf SiglerWhile we're on the topic of bashing Sig and Co., allow me to share my recent fuckery with Grok. I asked it to draw Ron Cohen as a dictator and worked from there.

View attachment 7714182

View attachment 7714179

View attachment 7714180

View attachment 7714184

View attachment 7714185

I think the last one came out the best.

And of course, what's really funny about giving him a Hitlerstache is that he's a fucking Jew.

Internet-Based Lobotomy

kiwifarms.net

- Joined

- Jun 5, 2025

I'm not sure how anyone can spin a slight trigger depression + nearly any form of slide manipulation causing a round to fire as anything other than bad. Granted this is a pretty small sample size of a few YouTube videos but I'd rather err on the side of caution with the recent string of Sig related incidents than risk my balls to protect my brand loyalty. Doubly so when it's being used as a duty weapon where it'd be many times more likely to be subjected to both trigger depression and slide manipulation. Of course Siggers could just do this same test and overshadow the few tests we've seen if they DON'T drop the striker.Tl;dw- People unfamiliar with how guns actually work are afraid of the 320, but Sig has the cheese touch now because of their mishandling of the optics.

- Joined

- Jun 5, 2020

- Joined

- Oct 6, 2021

Zastava 99 Machinepistol with a CZ-75 Auto style front magazine grip

Tri-mag M1 Carbine used by Cuban insurgents

Australian Automatic Arms SAC

9A-91

Bottom is a Liberty Pen Gun, top is a Pen-15

Victrix Gladio PS-A1 and it's weird suppressor ready muzzle device

I found some guy who claims to be designing an entirely new form of Caseless ammunition firing rifle, and from what I understand it sounds absolutely bizarre in its function using niche technology dating back centuries

Project name is BrashZero

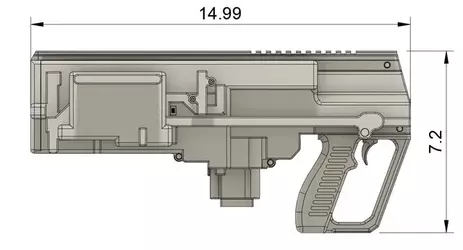

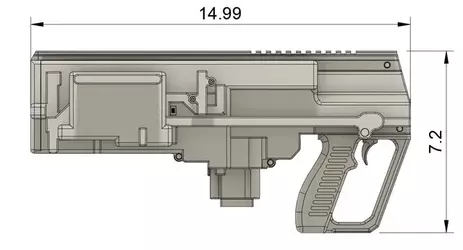

Chambered in 5.56 using a modified AR barrel it measure in at 15in with a 7.5in barrel

Website

Website archives

Features

Operation

Prior Art (It vs G11)

Archive of the creator's reddit posts going back 6 hours containing most of the responses he's given people asking questions

Thread where he introduces it to the world

Claims

-Uses Standard 5.56 projectiles and powder (more on that in a minute)

-Designer claims that you'll be able to carry 460 rounds that weighnas much as 210 conventional 5.56

-Design is wholly mechanical, no electronics involved (You'll see why that's weird momentarily)

-If I understand how this thing is supposed to work it works a little like this

-You manually charge the gun to get started just like any other semi auto firearm

-By doing so you chamber a bullet (remembers just a bullet, this is a caseless design)

-Sometime after (supposedly milliseconds based on his description of this rifle having military applications) propellant (standard COTS smokeless) is by some undisclosed means inserted into the chamber from what he describes as a "reservoir" that he compares to a gas tank, that he stresses is far removed from any source of heat, meaning that it's far from the chamber or gas system) which implies some form of internal duct work.

-You then somehow ignite the propellant by pulling the trigger (which I don't know how you're supposed to without electric ignition, because remember, no electronics and there's absolutely no way to you can fanangle a new, loose primer into place with every single round)

-The propellant ignites, pushing the bullet down the barrel, cycling the gun and repeating the process.

-He claims that the system can be used with a belt feed thus implying full auto, so whatever system he claims to have devised for feeding the powder is fast acting enough to keep pace with even a relatively low RPM.

-Powder feeding mechanism operates via "Transporter and Plunger"

This thing sounds like a space age version of one of those fancy repeating flintlocks from centuries ago that cost the equivalent of a year's wages

This guy uses a lot of words, so either he's a genius or bullshitting

Now you see I thought this guy was some kind of Delusional idiot like Fry Tech (bro magnetic delay totally works bro I may have a face tattoo but I have a patent bro) or Pepe Liberator guy (I really have to get around to doing a write up on the Pepe Liberator one of these days) or one of those Fosscad kiddies who "design" guns by drawing them with no detail in 2D on graph paper but then I thought his Reddit username sounded familiar and it turns out I've written about his designs before in this thread

What's really screwing with me besides the powder delivery is how are you supposed to achieve non electric, (presumably) non chemical, purely mechanical ignition. The only thing I can think of is some kind of futuristic, highly refined flint/wheellock system bit I can't think of how you would begin to integrate something like that.

The "About the designer" page make some rather hefty claims

The only Jonathan Blecher who has even a tangential connection to anything listed on that page is this Miami based DUI lawyer (page says the designer graduated from Florida State University College of Law)

Can someone better at digging up info take a look?

Tri-mag M1 Carbine used by Cuban insurgents

Maxi-14 pump action system for Mini-14 rifles

Australian Automatic Arms SAC

9A-91

Bottom is a Liberty Pen Gun, top is a Pen-15

Victrix Gladio PS-A1 and it's weird suppressor ready muzzle device

I found some guy who claims to be designing an entirely new form of Caseless ammunition firing rifle, and from what I understand it sounds absolutely bizarre in its function using niche technology dating back centuries

Project name is BrashZero

Chambered in 5.56 using a modified AR barrel it measure in at 15in with a 7.5in barrel

Website

Website archives

Features

Operation

Prior Art (It vs G11)

Archive of the creator's reddit posts going back 6 hours containing most of the responses he's given people asking questions

Thread where he introduces it to the world

Claims

-Uses Standard 5.56 projectiles and powder (more on that in a minute)

-Designer claims that you'll be able to carry 460 rounds that weighnas much as 210 conventional 5.56

-Design is wholly mechanical, no electronics involved (You'll see why that's weird momentarily)

-If I understand how this thing is supposed to work it works a little like this

-You manually charge the gun to get started just like any other semi auto firearm

-By doing so you chamber a bullet (remembers just a bullet, this is a caseless design)

-Sometime after (supposedly milliseconds based on his description of this rifle having military applications) propellant (standard COTS smokeless) is by some undisclosed means inserted into the chamber from what he describes as a "reservoir" that he compares to a gas tank, that he stresses is far removed from any source of heat, meaning that it's far from the chamber or gas system) which implies some form of internal duct work.

-You then somehow ignite the propellant by pulling the trigger (which I don't know how you're supposed to without electric ignition, because remember, no electronics and there's absolutely no way to you can fanangle a new, loose primer into place with every single round)

-The propellant ignites, pushing the bullet down the barrel, cycling the gun and repeating the process.

-He claims that the system can be used with a belt feed thus implying full auto, so whatever system he claims to have devised for feeding the powder is fast acting enough to keep pace with even a relatively low RPM.

-Powder feeding mechanism operates via "Transporter and Plunger"

This thing sounds like a space age version of one of those fancy repeating flintlocks from centuries ago that cost the equivalent of a year's wages

This guy uses a lot of words, so either he's a genius or bullshitting

Now you see I thought this guy was some kind of Delusional idiot like Fry Tech (bro magnetic delay totally works bro I may have a face tattoo but I have a patent bro) or Pepe Liberator guy (I really have to get around to doing a write up on the Pepe Liberator one of these days) or one of those Fosscad kiddies who "design" guns by drawing them with no detail in 2D on graph paper but then I thought his Reddit username sounded familiar and it turns out I've written about his designs before in this thread

Found an upstart manufacturer that is making Longstroke AR's

What's really screwing with me besides the powder delivery is how are you supposed to achieve non electric, (presumably) non chemical, purely mechanical ignition. The only thing I can think of is some kind of futuristic, highly refined flint/wheellock system bit I can't think of how you would begin to integrate something like that.

The "About the designer" page make some rather hefty claims

The only Jonathan Blecher who has even a tangential connection to anything listed on that page is this Miami based DUI lawyer (page says the designer graduated from Florida State University College of Law)

Can someone better at digging up info take a look?

- Joined

- Feb 26, 2019

A "thinking man" CNC tests his 320:

Tl;dw- Trigger slack is taken up to the wall, wiggles slide, gun fires...

"See? A trigger pull is still needed to fire!" and

"I'm not going to respond to any arguments, haters are wrong."

"See? A trigger pull is still needed to fire!" and

"I'm not going to respond to any arguments, haters are wrong."

- Joined

- Jan 1, 2023

It's a tolerance stacking issue. This is what happens when you outsource parts manufacturing to Indoniggers.A "thinking man" CNC tests his 320:

Tl;dw- Trigger slack is taken up to the wall, wiggles slide, gun fires...

"See? A trigger pull is still needed to fire!" and

"I'm not going to respond to any arguments, haters are wrong."

- Joined

- Dec 14, 2022

Does it potentially use a compression ignition system?What's really screwing with me besides the powder delivery is how are you supposed to achieve non electric, (presumably) non chemical, purely mechanical ignition. The only thing I can think of is some kind of futuristic, highly refined flint/wheellock system bit I can't think of how you would begin to integrate something like that.

Basically you have a piston, that compresses air, the air heats up, ignites whatever is in the piston. Typically these are just hand powered and used as novelty firestarters but I can definitely see the potential of using it as the basis of a primerless/caseless ammunition. The piston would be spring loaded, you pull the trigger and it's basically just as fast as a firing pin. The ignition resets the piston and you're ready for the next shot. I don't think this would be good for full auto applications because you'll get some intense heat build-up which could lead to cooking off unintended rounds after you try to stop shooting, but that could be designed around. Maybe we've finally made it to the future where our guns have swappable heatsinks, maybe that could even be built into the magazine since you don't have to worry about your cartridges cooking off since the propellant is elsewhere

I actually have in my head a system for how this could work, I might try and draw it out

- Joined

- Oct 6, 2021

Wouldn't that require all components involved to form an at least relatively airtight seal? Airtight seals are fairly achievable but I've never heard of one being achieved in the context of a firearm action. I'm still going with the hyper advanced flint/wheellock theoryDoes it potentially use a compression ignition system?

View attachment 7715461

Basically you have a piston, that compresses air, the air heats up, ignites whatever is in the piston. Typically these are just hand powered and used as novelty firestarters but I can definitely see the potential of using it as the basis of a primerless/caseless ammunition. The piston would be spring loaded, you pull the trigger and it's basically just as fast as a firing pin. The ignition resets the piston and you're ready for the next shot. I don't think this would be good for full auto applications because you'll get some intense heat build-up which could lead to cooking off unintended rounds after you try to stop shooting, but that could be designed around. Maybe we've finally made it to the future where our guns have swappable heatsinks, maybe that could even be built into the magazine since you don't have to worry about your cartridges cooking off since the propellant is elsewhere

I actually have in my head a system for how this could work, I might try and draw it out

Also, I think the Rape Train may be leaving the station and heading directly for Sig Saar's feces encrusted Anus

The family of the Airman killed has apparently retained the services of the law firm who secured a $1.2B settlement over the Surfside Condo collapse

@AnOminous

You know law stuff, are these guys capable of legally/financially suing a major arms manufacturer that provides the US Army's service rifle to death?

- Joined

- Dec 28, 2014

It's very, very difficult to win a gun case, but actual product defects are another thing. It's not going to kill them. The reputational damage and potentially losing government contracts is going to hurt them a lot more and might thoroughly tarnish the brand.@AnOminous

You know law stuff, are these guys capable of legally/financially suing a major arms manufacturer that provides the US Army's service rifle to death?

Polock

kiwifarms.net

- Joined

- Jan 17, 2022

Sweet, its a bomb!Sometime after (supposedly milliseconds based on his description of this rifle having military applications) propellant (standard COTS smokeless) is by some undisclosed means inserted into the chamber from what he describes as a "reservoir" that he compares to a gas tank, that he stresses is far removed from any source of heat, meaning that it's far from the chamber or gas system) which implies some form of internal duct work.

>he stresses its far removed from any source of heat

Sweet, its a bomb!

I really love wacky stuff like this even if it only just barely works and sucks ass.

Please do.I really have to get around to doing a write up on the Pepe Liberator one of these days

- Joined

- Aug 17, 2022

Proof that not all machinists are smarter than their machine. No other gun on the planet will fire like this. I can literally pull both my VP9 and my G19 triggers to the wall, and wiggle the slides all fucking day, nothing happens. You know why? Because they aren't shit guns.A "thinking man" CNC tests his 320:

Tl;dw- Trigger slack is taken up to the wall, wiggles slide, gun fires...

"See? A trigger pull is still needed to fire!" and

"I'm not going to respond to any arguments, haters are wrong."

- Joined

- Dec 14, 2022

It doesn't necessarily need to be airtight, just 'pretty good'. Think the pistons and piston rings in an automotive engine. Diesel engines work on compression, they use super low octane (low stability) fuel that detonates under relatively low pressure rather than through the use of a spark plug. Mentioning that, I wonder if it potentially uses some kind of aerosolized or gas based propellant rather than solid gunpowder. That would theoretically be easier to work with as you could run the action 'rich' (excess fuel) to keep it coolWouldn't that require all components involved to form an at least relatively airtight seal? Airtight seals are fairly achievable but I've never heard of one being achieved in the context of a firearm action. I'm still going with the hyper advanced flint/wheellock theory

Here's what I came up with. I'm not an artist or an engineer so feel free to ask questions (or call me a retard lol)

Using a fuel injector of some kind would actually make this simpler and more reliable and goes to the 'gas tank' mentioned in your notes. Thinking it through a second time I'm actually 99% sure that it uses either a liquid or gas based propellant rather than solid, so swap the powder hopper in my design for a fuel tank of some kind, something like propane/butane/etc would be my guess

Rather than trying to draw it again, here's the diagram for a one-cylinder engine

Drop the spark plug

The crankshaft provides energy through spring power rather receiving it and sending it to the transmission

When the piston goes up a burst of fuel and air enters, ignites through compression

The exhaust valve is the barrel, compressed exhaust fires the projectile and resets the action, just like a standard rifle

It's basically a closed-open-bolt. I like it lol

Last edited:

- Joined

- Oct 6, 2021

He explicitly states he's using standard propellant (and uses terms that are decidedly not aerosol related "Transporter and Plunger") and I think if he wanted to obfuscate the fact that he wasn't he would say something vague about "proprietary, patent pending technology".It doesn't necessarily need to be airtight, just 'pretty good'. Think the pistons and piston rings in an automotive engine. Diesel engines work on compression, they use super low octane (low stability) fuel that detonates under relatively low pressure rather than through the use of a spark plug. Mentioning that, I wonder if it potentially uses some kind of aerosolized or gas based propellant rather than solid gunpowder. That would theoretically be easier to work with as you could run the action 'rich' (excess fuel) to keep it cool

Here's what I came up with. I'm not an artist or an engineer so feel free to ask questions (or call me a retard lol)

View attachment 7715639

Using a fuel injector of some kind would actually make this simpler and more reliable and goes to the 'gas tank' mentioned in your notes. Thinking it through a second time I'm actually 99% sure that it uses either a liquid or gas based propellant rather than solid, so swap the powder hopper in my design for a fuel tank of some kind, something like propane/butane/etc would be my guess

Rather than trying to draw it again, here's the diagram for a one-cylinder engine

View attachment 7715658

Drop the spark plug

The crankshaft provides energy through spring power rather receiving it and sending it to the transmission

When the piston goes up a burst of fuel and air enters, ignites through compression

The exhaust valve is the barrel, compressed exhaust fires the projectile and resets the action, just like a standard rifle

It's basically a closed-open-bolt. I like it lol

This guy is either a moron bullshitter high on his own ego supply or he's the greatest Arms Designer since Stoner.

- Joined

- Jan 1, 2023

He calls himself "thinking man" (which seems like a psychological red flag) and then shits the bed with the claim that this isn't an issue, despite reproducing the exact same thing Wyoming Gun Project did and had correctly asserted is an issue.Proof that not all machinists are smarter than their machine. No other gun on the planet will fire like this. I can literally pull both my VP9 and my G19 triggers to the wall, and wiggle the slides all fucking day, nothing happens. You know why? Because they aren't shit guns.

Among Us Gaming

kiwifarms.net

- Joined

- Sep 16, 2024

Unrelated to the sig stuff, but I've been doing some research lately, and it amuses me greatly how nearly every single AR15 alternative-derivative is just the BRN 180 but worse.

Also AKs get style points but no utility points in comparison

Also AKs get style points but no utility points in comparison

Internet-Based Lobotomy

kiwifarms.net

- Joined

- Jun 5, 2025

I will

I will grant him that .019" difference in horizontal movement doesn't seem like a lot to most people. However it's a weird conclusion to come to for someone that is presumably a machinist who presumably has to work on tolerances that are another decimal place away. I'd be interested to see this tested with a trigger scale as well so we can get an idea of the in commanded discharge range to total trigger weight to fire.A "thinking man" CNC tests his 320:

Tl;dw- Trigger slack is taken up to the wall, wiggles slide, gun fires...

"See? A trigger pull is still needed to fire!" and

"I'm not going to respond to any arguments, haters are wrong."

I think it'd be a cool concept nonetheless. Wish he at least had a physical mock up of the internals to show or better yet a working model. Some static 3D model isn't very titillating and his words are just a little too vague to make the pieces fit. It would be funny if his solution was a Columbus' egg type situation.This guy is either a moron bullshitter high on his own ego supply or he's the greatest Arms Designer since Stoner

- Joined

- Jan 1, 2023

- Joined

- Apr 18, 2019

Since the AR-18 was introduced to the international market to lukewarm reception due to it being "cheap" in both construction and cost, it has been ripped off by European countries. It only stands to reason that it continues.Unrelated to the sig stuff, but I've been doing some research lately, and it amuses me greatly how nearly every single AR15 alternative-derivative is just the BRN 180 but worse.

Gurney Halleck

kiwifarms.net

- Joined

- May 8, 2025

Someone should try doing that screw + shake awake test with a P365, that should definitively answer how badly Sig fucked up there.