How I use my 3d printer, usually not to print actual items. About half of what I print is jigs, spacers, etc.

Today's project is working on the electronics enclosure for my CNC router. I need a USB and Ethernet port. These are both square/rectangular.

Cutting those holes accurately at my skill level in a metal enclosure sucks.

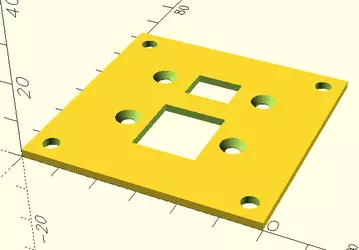

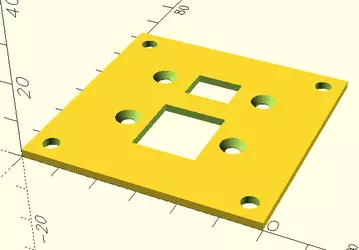

So, I make a 3d printed cover panel:

But the metal still needs to be cut. What's the easiest thing to cut in a metal enclosure... circles.

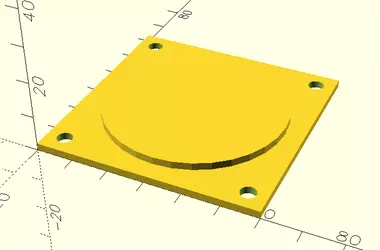

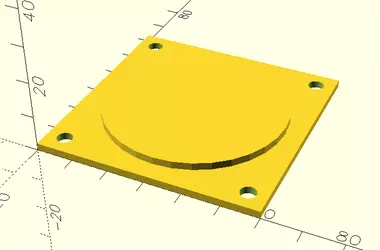

So, I used the holesaw to cut a 2" (50.8mm) hole in the enclosure and 3d printed this:

Set the jig so the round is in the hole, use a square to align it. Mark the first hole. Drill it, screw the jig to the enclosure, mark and drill the remaining holes, throw away jig, deburr all the fucking holes, put the final coverplate on.