- Joined

- May 29, 2018

Oh right, here’s a pic of the completed Omniwrench. The silver portions were printed with Elegoo’s silver Silk PLA, the black portions with Sunlu’s Matte Black PLA, and the blue portions with CC3D Sapphire Blue Silk PLA.

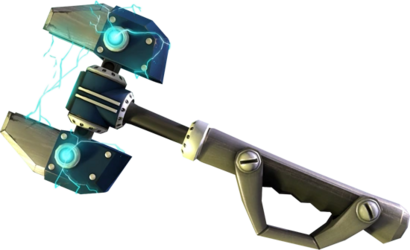

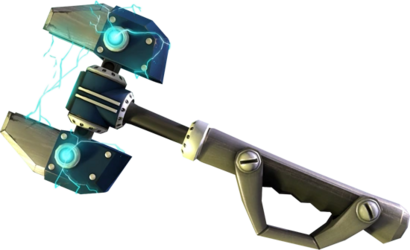

And here’s a piece of key art of the same Omniwrench.

Considering the differences between the key art and the finished print I probably would’ve had an “easier” time printing it in a “paint-friendly” PLA color and doing the whole sanding-priming-painting-sealing process to it. That said I like it enough to consider it a successful print.

But there are some minor issues, most notably these visible gaps in the prints.

And here’s a piece of key art of the same Omniwrench.

Considering the differences between the key art and the finished print I probably would’ve had an “easier” time printing it in a “paint-friendly” PLA color and doing the whole sanding-priming-painting-sealing process to it. That said I like it enough to consider it a successful print.

But there are some minor issues, most notably these visible gaps in the prints.

I’m pretty handy with precision so I think my fingers will be safe with a soldering iron. I also realized that a soldering iron could also help me combine spools of like filament from the same manufacturer. I managed to do that with a nice $10 filament splicer tool and a lighter but I just can’t seem to do that with the other filaments I have.If you can manage not to toast your fingers like so many tasty hotdogs, you can really do a lot with PLA welding once you get a little practice. I have even rewelded some BattleTech figures with a bent 9usd Weller "soldering iron", so it's a skill worth learning because you can salvage a lot of 'ruined' prints.