- Joined

- Dec 29, 2014

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tesla Hate Thread - oh and come seethe about EVs in general with me

- Thread starter Nguyen Van Phuoc

- Start date

- Joined

- Nov 19, 2018

- Joined

- Jul 1, 2015

The Tesla Cybertruck is such a piece of shit the plastics inside are breaking apart on first inspection for some people.

He ended up trading the Cybertruck, to get a Cadillac Lyriq:

Capacitive touch controls, electronic faults, and even the center console broke, and the SINGLE LONG ASS SCREEN that will cost as much a used car to fix, doesn't bode well for the Lyriq either.

And Porsche will continue to offer ICE Cayennes until the 2030s, and is rolling back on their EV plans somewhat, due to waning demand.

Last edited:

wtfNeedSignUp

kiwifarms.net

- Joined

- Dec 17, 2019

If modern manufacturers could lock your car while you are driving 80 MPH with your entire family in it, due to a missed payment on some DLC, they would do it in a heartbeat.

- Joined

- Mar 12, 2022

oh what's this . Eurozone has pissed billions into an EV black hole , must be a day that ends in y.

Weird how no one is buying these cheaper overall cars.

Weird how no one is buying these cheaper overall cars.

- Joined

- Mar 30, 2023

you need to refresh the page often for that link https://archive.is/Q1HMDoh what's this . Eurozone has pissed billions into an EV black hole , must be a day that ends in y.

Weird how no one is buying these cheaper overall cars.

Profits at the German auto giant Mercedes plunged on Friday as sales of its slick new range of electric vehicles (EVs) went into freefall. Porsche abandoned its sales targets for battery-powered cars amid waning demand from customers. Ford is losing nearly $50,000 (£39,000) on every EV it sells, while Tesla’s profits dropped 45pc. Meanwhile, battery manufacturers such as Germany’s Varta are getting wiped out.

Over the last few days, it has become clear that the EV industry is on the brink of collapse. Hundreds of billions of euros, dollars and pounds have been pumped into this industry by political leaders and the subsidy junkies that surround them – and it is surely time they were held to account for the vast quantities of taxpayer cash that has been wasted.

In the last few days alone, there has been a steady stream of bad news from auto manufacturers. Mercedes, the company founded by Gottlieb Daimler that pioneered petrol driven cars, is struggling to replicate that success in the battery version. Group net profits were down 21pc on Friday, mostly on falling sales of its new range of EVs. Earlier in the week, its great rival Porsche watered down plans for its electric models.

Across the Atlantic, Ford reported that profits were down by 35pc in the latest quarter amid losses in its EV unit. And Tesla slashed prices and offered generous financing deals to try and revive flagging demand.

It is even worse for component manufacturers. Shares in Germany’s Varta are down by 70pc over the last month amid reports that the company may have to be rescued from bankruptcy after making heavy losses on batteries for hybrid sports cars. This week, the Belgium chemicals group Umicore announced a €1.6bn (£1.4bn) hit, as manufacturers warned of waning EV demand, and it postponed plans for a battery recycling plant.

The list goes on and on. In reality, the EV balance sheet looks to be awash with red ink. It is not hard to work out why. Costs are too high, as companies such as Ford have discovered, with electric cars much more expensive to produce than their traditional petrol rivals, and with shortages of critical materials pushing prices higher all the time.

There is too much capacity in the industry, with companies over-investing in too many factories and distribution centres. Demand for the end product has started to crumble, with consumers increasingly nervous over what may become obsolete technology. Insurance and maintenance costs are proving far higher than expected for many, once the vehicles are actually on the road.

And all that was before the Chinese entered the market with a new range of slick, cheap vehicles. The word “bloodbath” is used too often in business journalism. But right now, it may be the only one appropriate to describe the state of the Western EV industry.

Surely it is time that political heads started to roll for the catastrophe that is now unfolding. Policymakers, under pressure from industrial and climate change lobby groups, picked this “winner” and spent eye-watering amounts of taxpayer money on it.

In 2019, France’s President Macron grandly announced a Franco-German plan to dominate battery production, with €700m invested by France and another €1bn in Germany. The EU proudly boasts that €80bn has been invested in the “EV value chain” as part of its Green New Deal, but when the books are finally opened it is unlikely they will be good.

The situation is even worse in the US. The Biden administration recently awarded nearly $2bn in grants to help restart or expand EV manufacturing and assembly sites across eight states, which feels like throwing good money after bad. It has offered tens of billions in subsidies of more than $7,000 per vehicle sold, and even more in building the infrastructure, including one $7.5bn scheme to install chargers that ended up with only seven actually built (which works out at more than $1bn each for what is basically just a plug).

Even in this country, where our political class was largely too incompetent to back any projects, money was poured into the ill-fated Britishvolt project, and it remains to be seen how much is finally given to India’s Tata for its new EV battery factory in Somerset.

Economists have long warned that net zero provides a golden opportunity for waste and rent-seeking. But some elites chose not to listen. We should start holding them accountable. Lobbyists argued for the subsidies, civil servants supported them, and finance ministers enthusiastically virtue signalled with other people’s money.

But too much investment creates overcapacity. Markets are better at deciding which technologies work than politicians, and if there is a genuine demand for a product then no one has to receive a grant to manufacture it, since the potential profits to be made will be incentive enough.

The carnage in the EV industry is only just getting started and already it has cost billions.

- Joined

- Nov 16, 2022

RIP Varta investors. I wonder if Germany will bail them outoh what's this . Eurozone has pissed billions into an EV black hole , must be a day that ends in y.

Weird how no one is buying these cheaper overall cars.

- Joined

- Jul 1, 2015

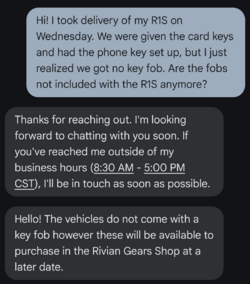

The 2025 Rivian R1S and R1T will not include a keyfob for owners. Rivian also said that they may sell key fobs for those models at a later date, but there's the emphasis on "may".

Here's a conversation from a new Rivian owner, and the salesperson, about the said lack of key fob:

Here's a conversation from a new Rivian owner, and the salesperson, about the said lack of key fob:

- Joined

- Jul 1, 2015

Tesla has recalled 1.8 million of their cars, because the car may not detect an unlatched frunk, which can cause it to open it while driving. The remedy for it is just an OTA update to warn the user if the frunk is not fully closed, which is the bare minimum of a recall fix.

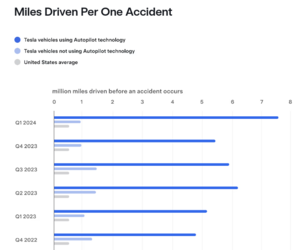

And to no surprise, Tesla changing from using sensors to just cameras for their FSD system, caused the increased number of autopilot crashes.

And to no surprise, Tesla changing from using sensors to just cameras for their FSD system, caused the increased number of autopilot crashes.

- Joined

- Mar 4, 2019

10 year old car with 40k miles on the clock, functionally totalled because it has lost all two thirds of its range. Hoovie desperately copes that EVs are actually still great and ICE is dying, but it's obvious to anyone that BEVs are a technological dead end.

- Joined

- Nov 19, 2020

I always wondered how Tesla counts "crashes without autopilot engaged." I bet there is a good chance the passenger is going to grab the wheel, or stomp the breaks at some point right before impact. Depending on how you count a crash with/without autopilot could really affect the results. Who's auditing if they are reporting the truthful data? For instance if someone is driving and manually disengages the autopilot a second or two before an accident they could conceivably count that as a "crash without autopilot engaged." Volkswagen faked emissions data for years, I don't seen anyone auditing this self published stuff.

wtfNeedSignUp

kiwifarms.net

- Joined

- Dec 17, 2019

I do you fuck up a frunk design this badly that it opens if it's isn't locked? How do you fuck a lock for several kilos weight pressing on it? Why even recall if you could do the warning through a software update, or in true clownworld fashion they update the car rather than the lock?Tesla has recalled 1.8 million of their cars, because the car may not detect an unlatched frunk, which can cause it to open it while driving. The remedy for it is just an OTA update to warn the user if the frunk is not fully closed, which is the bare minimum of a recall fix.

And to no surprise, Tesla changing from using sensors to just cameras for their FSD system, caused the increased number of autopilot crashes.

- Joined

- Jul 11, 2022

I saw a white Cybertruck on my way to get some food earlier. It was staggeringly ugly and jarringly out of place.

The silver ones aren't much better either. I think it might kinda work in black like a stealth fighter but I'd have to see one in person to be sure.

The silver ones aren't much better either. I think it might kinda work in black like a stealth fighter but I'd have to see one in person to be sure.

The ten years hits perfect. I'm working on a 2014 Honda CR-V with a VTC Actuator rattle. The common on the later K24 engines. The replacement part is 80 to 200 for aftermarket all the way to the Honda part. Job can be done in <2 hours. If the timing chain is worn, sometimes happens from the bad part, replacement parts are 140 to 350. Longer job, 6 hours for a fast mechanic.10 year old car with 40k miles on the clock, functionally totalled because it has lost all two thirds of its range. Hoovie desperately copes that EVs are actually still great and ICE is dying, but it's obvious to anyone that BEVs are a technological dead end.

Parts can be had online, auto parts stores, dealerships, and scrap yards.

Battery replacement? Impossible to do or hacked together fireball in waiting. Fucking dumbass. The whole problem is that your energy storage is a black box ticking down to nothing.

- Joined

- Dec 19, 2022

The issue is threefold, lithium batteries, deep cycles, and fast charging. Lithium batteries already deteriorate fairly quickly just through normal use, but if you charge them above ~75% and discharge below ~25% you're losing a lot more capacity per cycle, and if you then fast-charge the battery you're losing even more capacity. They're a pretty terrible choice for a car, electric cars already have fairly low range, imagine halving that? Imagine then waiting for three or four hours for the battery to charge back up at a healthy rate? For the daily commute that's fine, but most people with cars are also going to want to use them for other, longer journeys, too. A better choice would have been nickel-cadmium storage cells, the sort used in industry and UPSes. They're rated for tens of thousands of cycles. Unfortunately they also self-discharge, need to be refilled with water fairly regularly, and have an abominably low capacity:weight ratio. That's pretty much the only thing lithium batteries have going for them, they're very energy dense. Yet electric cars are still twice the weight of a petrol car.

I still hold that electric cars ought to have a fairly small battery for everyday use, and a tiny diesel powerplant to keep it going when that battery runs out. Kind of like how trains work. A tiny battery wouldn't be ruinously expensive to just swap out once it begins to run out of cycles, can be trickle-charged overnight/while parked at work, and can function as a buffer such that the generator can be made significantly smaller than the engine of a comparable car. In everyday use you only need enough capacity to get to work, to the grocery store, and back home, after all. Cars don't need many joules to keep rolling, most of the time most of your engine volume is wasted. If you could instead dimension it such that the generator only puts out just a little bit more than the car needs to keep rolling, the battery can kick in extra power in hills or while accelerating. You can also use a flywheel to capture energy while braking, which is more efficient than turning the motors into dynamos.

I still hold that electric cars ought to have a fairly small battery for everyday use, and a tiny diesel powerplant to keep it going when that battery runs out. Kind of like how trains work. A tiny battery wouldn't be ruinously expensive to just swap out once it begins to run out of cycles, can be trickle-charged overnight/while parked at work, and can function as a buffer such that the generator can be made significantly smaller than the engine of a comparable car. In everyday use you only need enough capacity to get to work, to the grocery store, and back home, after all. Cars don't need many joules to keep rolling, most of the time most of your engine volume is wasted. If you could instead dimension it such that the generator only puts out just a little bit more than the car needs to keep rolling, the battery can kick in extra power in hills or while accelerating. You can also use a flywheel to capture energy while braking, which is more efficient than turning the motors into dynamos.

Bonesjones

kiwifarms.net

- Joined

- Jan 27, 2021

I rode in a Tesla Uber recently, first car I've been in with a broken seat belt latch since the 80s

- Joined

- Mar 4, 2019

In this case, the "recall" is pure legal jargon for "do the thing". They have to call it that to satisfy the transport admin rules after the issue was reported. There's a regular cadence of this kind of recall for modern cars, where the issue is caused or mitigated in software and where the "recall" is an ota update without the car seeing a mechanic. It's indicative of an underlying problem: cars are now computers that happen to have wheels on them and are powered by the minimum viable product emitted by teams of poorly paid, overworked, under qualified software developers.Why even recall if you could do the warning through a software update

Meriasek

kiwifarms.net

- Joined

- May 16, 2020

EV fans will claim that battery tech got a lot better now and there's very little degradation, and also that replacing a battery isn't complicated to do in more cars. Still expensive, but not that labor intensive.The ten years hits perfect. I'm working on a 2014 Honda CR-V with a VTC Actuator rattle. The common on the later K24 engines. The replacement part is 80 to 200 for aftermarket all the way to the Honda part. Job can be done in <2 hours. If the timing chain is worn, sometimes happens from the bad part, replacement parts are 140 to 350. Longer job, 6 hours for a fast mechanic.

Parts can be had online, auto parts stores, dealerships, and scrap yards.

Battery replacement? Impossible to do or hacked together fireball in waiting. Fucking dumbass. The whole problem is that your energy storage is a black box ticking down to nothing.

Finally, there'll be cope about how solid state batteries are right around the corner.

They have been right around the corner for a decade.

wtfNeedSignUp

kiwifarms.net

- Joined

- Dec 17, 2019

It gets exponentially worse with the move to minimise physical components with electrical components, massively increasing the likelihood of failure.In this case, the "recall" is pure legal jargon for "do the thing". They have to call it that to satisfy the transport admin rules after the issue was reported. There's a regular cadence of this kind of recall for modern cars, where the issue is caused or mitigated in software and where the "recall" is an ota update without the car seeing a mechanic. It's indicative of an underlying problem: cars are now computers that happen to have wheels on them and are powered by the minimum viable product emitted by teams of poorly paid, overworked, under qualified software developers.

Do car manufacturers give you a guaranteed money back for battery time/usage degradation? Anything below 20 years is a scam. And even if solid state batteries come around, who says old EVs will be able to use them?EV fans will claim that battery tech got a lot better now and there's very little degradation, and also that replacing a battery isn't complicated to do in more cars. Still expensive, but not that labor intensive.

Finally, there'll be cope about how solid state batteries are right around the corner.

They have been right around the corner for a decade.

- Joined

- Apr 30, 2023

This is more or less how PHEVs work today except the engine is usually tuned more towards being nice to drive and not a wimp. But a new 16KWh battery, which is very small for an EV, is still going to run you $15k optimistically. More likely you'd be pulling one from another equivalent model car for around $5k but that starts to get dubious pretty quick when you consider battery recalls.I still hold that electric cars ought to have a fairly small battery for everyday use, and a tiny diesel powerplant to keep it going when that battery runs out. Kind of like how trains work. A tiny battery wouldn't be ruinously expensive to just swap out once it begins to run out of cycles, can be trickle-charged overnight/while parked at work, and can function as a buffer such that the generator can be made significantly smaller than the engine of a comparable car. In everyday use you only need enough capacity to get to work, to the grocery store, and back home, after all. Cars don't need many joules to keep rolling, most of the time most of your engine volume is wasted. If you could instead dimension it such that the generator only puts out just a little bit more than the car needs to keep rolling, the battery can kick in extra power in hills or while accelerating. You can also use a flywheel to capture energy while braking, which is more efficient than turning the motors into dynamos.